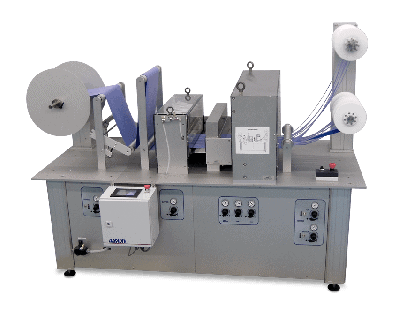

Material

Varying widths 3/8” – 12 ¾“ tape

Requirements

Unwind, slit, cut to length, and rewind material from roll

Our Solution

Using the building blocks of automation, several of our components were combined to provide a complete system.

- The roll of material is placed on a dancer unwind.

- From the unwind, the material is guided into the SLC-400 crush cut slitting station by a dancer accumulator. The crush cut slitter has a quick disconnect capability, which allows the operator to adjust the cutter blades easily.

- From the slitter station, the material will be pulled by the roll feeder into the TS-400 traveling knife, where the material will be perforated.

- A color touch screen allows the operator to program the lengths that they would like to be fed and cut.

- The material will be rewound by a differential shaft rewind station.

- All components are mounted on a free-standing work station to keep them in line.