Requirements:

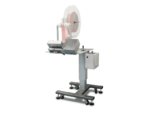

This application required placing absorbent pads onto trays.

Our Solution:

- AZCO made a CI-250 inserter with a dancer unwind.

- Material was placed on a roll.

- Material went through a dancer unwind and through idler rollers into the cut-to-length dispenser.

- Servo driven motors fed the material to the proper length.

- Rotary cutter cut the material to length.

- After the material was cut, a set of takeaway rollers took the material out from the unit.

- The unit was on a 45 degree angle, so the material and the tray below were going in line.

- There was a sensor that triggered when a tray went by and automatically dispensed a piece.

- Module design, free standing frame that rolled onto the packaging line.

- Easy installation, plugs into 110 VAC.

- Color operator control panel for easy setup and use.