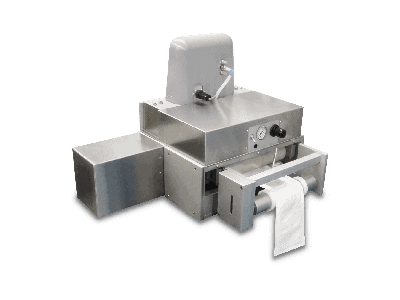

Material: 3/8” x 3″ wide pad, with sealed air between each pad.

Requirements

Accurately feed the pads and cut an 8” piece to a registered position in between the sealed areas. The pads needed to come out in a position to be handed to a secondary process. Cycle requirements were 80 cuts per minute.

Our Solution

We modified our standard FG-250 and added dual tractor drives to handle the three-dimensional padded product.

- We had eye registration to position the material in the right location to the knife.

- The unit was servo driven for high force and accuracy.

- A Smartknife option was included on the knife assembly for higher cycle rates.

- Infeed rollers with side guides guided the material into the tractor drive assembly.

- The tractor drive was dual driven with a gear drive system.

- There was a loop sensor to turn the unit on and off, so that the unit was always assured of material in the process.

- Unit required compressed air and 110 V power.

![212069_-_fg-250_sp_-_front[1]](https://www.azcocorp.com/wp-content/uploads/2021/02/212069_-_fg-250_sp_-_front1.png)