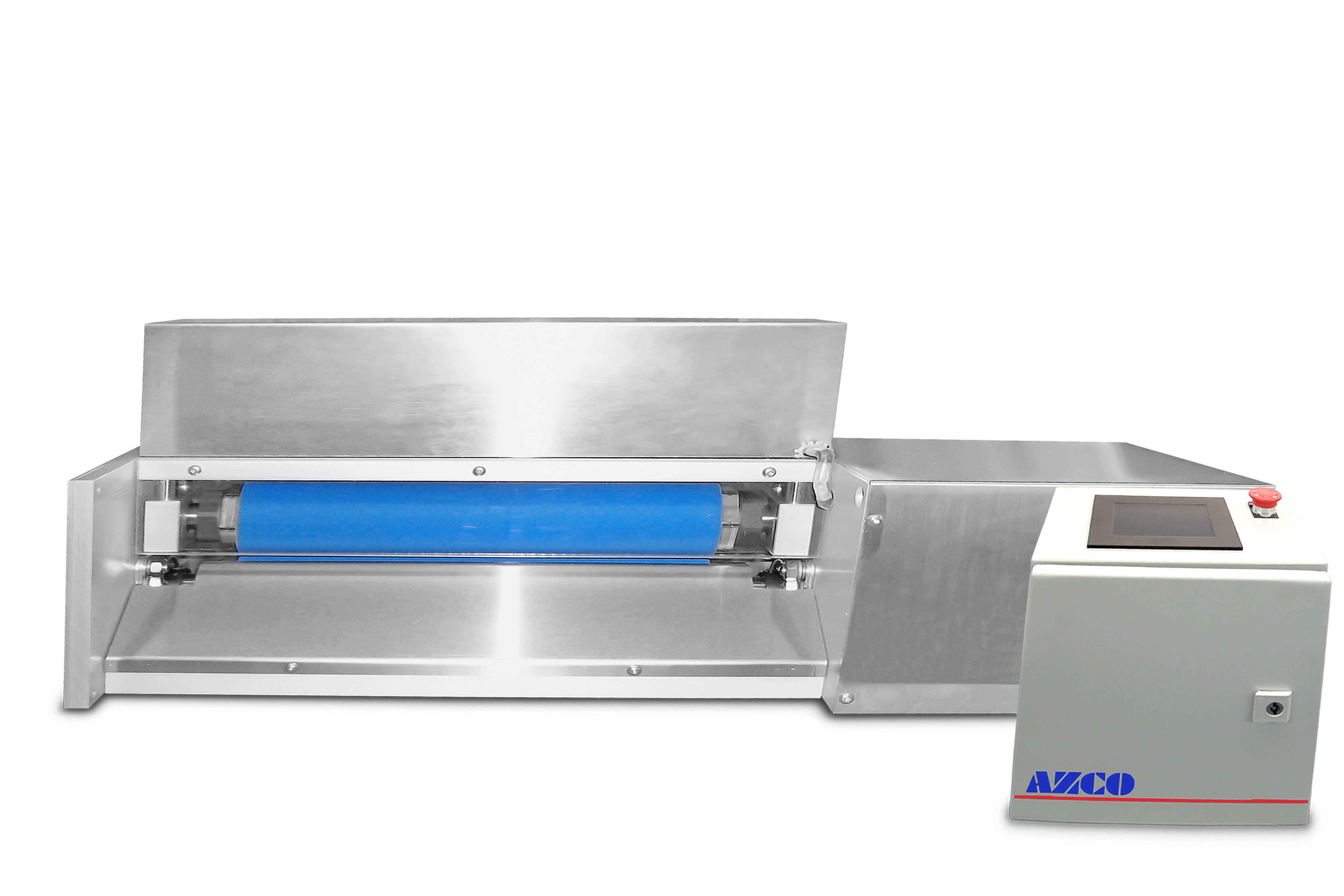

- PLC controlled with a color touch screen control panel for easy setup and operation.

- The unit can be operated in automatic or manual modes with a dry contact one shot input.

- Precision ground urethane drive rollers advance the material.

- The top idler roller is pneumatically pre-loaded – which includes a pneumatic cylinder, pressure regulator, air switch, and all necessary hosing and hardware for easier setup.

- The rollers are turned by a high accuracy, low maintenance indexing motor.

- Low maintenance; sealed bearings and servo motor drive system.