• Optic packages for sensing material going in and out of the station

• Cut-off modules that could be added to it

• Slitter stations that could bed added to the process

• Stands and mounts for easy bolt-on installation

• Optic registration where indexing to a specific mark, print or location is critical

• Custom sizes and designs are available to meet your specific application

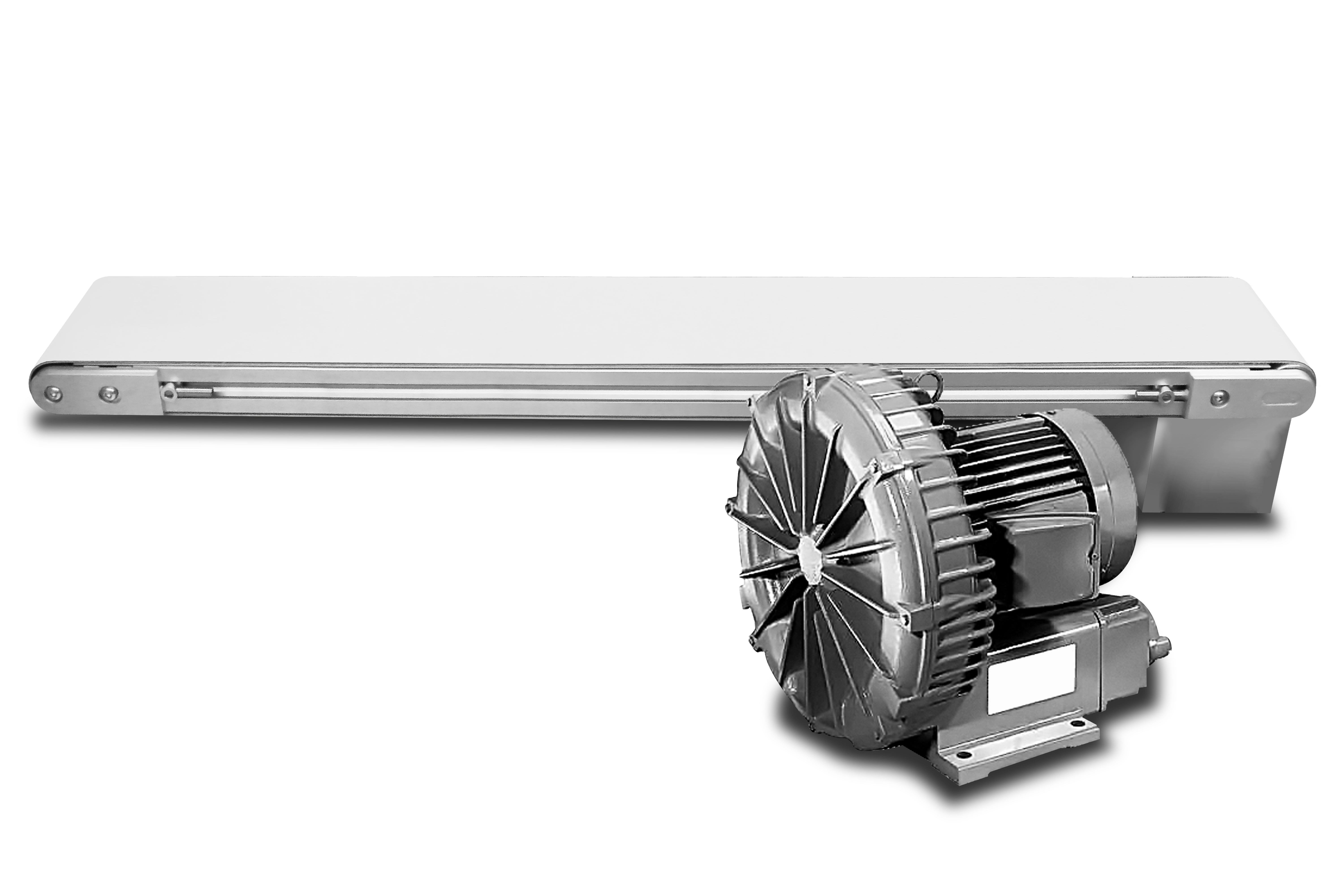

• High precision indexing of materials

• Indexing to precision lengths or speeds

• Compact in size

• Low profile transfer station fits in tight spaces

• Urethane continuous belt with vacuum ports

• No marking or marring on materials

• Integrated vacuum system

• Modular in design to give you the specific size and unit you need

• Ideal in many environments, including industrial environments, food and medical device industries

![conveyor_ac_drawing_001[1]](https://www.azcocorp.com/wp-content/uploads/2021/02/conveyor_ac_drawing_0011.png)

![conveyor_servo_drawing_001[1]](https://www.azcocorp.com/wp-content/uploads/2021/02/conveyor_servo_drawing_0011.png)