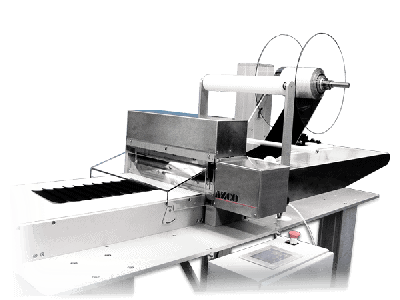

FG400SP CUT TO LENGTH

- The rollers are turned by a brushless stepper motor which provides high accuracy and low maintenance.

- Precision ground ball bearings, which require no lubrication.

- A PTFE coated material guide help direct the material from the drive rollers into the knife assembly.

- The knife assembly has thru hardened O-1 tool steel blades.

- Linear ball bearing bushings.

- Pneumatically operated knife assembly.

- An operator control panel is provided which includes a touch screen for easy setup and operation of the unit.

- 400mm cutting area.

- Pneumatic Preload Top Idler – Includes pneumatic cylinder, pressure regulator, air switch, and all necessary hosing and hardware for easier setup of the machinery.

- ½” thick aluminum plate mount the units.

- Infeed roller with adjustable collars.

- Material guides, rollers and opening of knife assembly accommodate webs with a thickness up to ½” thick.

DANCER UNWIND

- Cantilever design and construction powered by an AC motor and drive

- Drive maintains a loop – controlled by the dancer assembly – of material to prevent any web tension

- A manual control on the unwind tower controls the motor speed

- Standard unit can handle a roll of material with a maximum OD of 18″, a maximum width of 14″ on a 3″ ID core weighing less than 50 lbs.

ENCODER

Encoder wheel is used to measure the web for accurate cut-off. As the wheel turns it sends pulses to the PLC (self-calibrating with the encoder wheel). Tolerance of unit is between 0.25% and 0.5% for lengths of 2” to 65”.

OUTFEED CONVEYOR

- Continuous 78-80 durometer urethane belt.

- High strength anodized aluminum alloy frame.

- Unit is driven by a DC gear motor.

3 MODES OF OPERATION

- 1st mode has the unit measure the length of the piece from the rollers

- 2nd mode has the unit measure length from the encoder wheel

- 3rd mode has the unit measure length from the rollers and perform a check. The unit compares the measured length on the encoder wheel as compared to the rollers. If the lengths are outside a set tolerance, the unit will stop with an error.